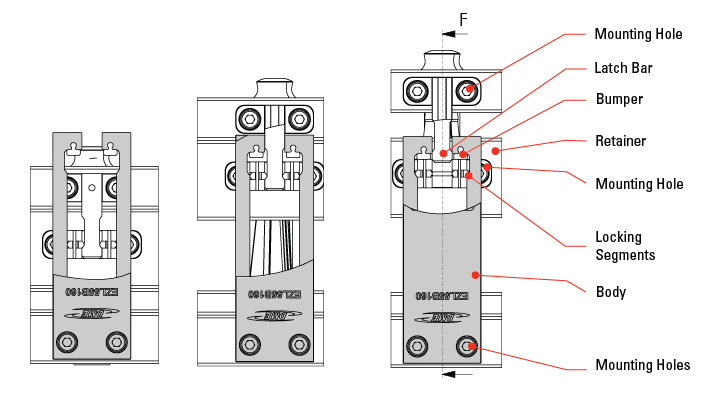

DME EZ-Latch

External Latch Locks

Featuring

- Pre-drilled Extended Latch Bars

- 2-Piece Latch Bar Adapter

- Built-in Delay

See how it works

Precise Positioning For A Variety Of Different Moulding Applications

DME’s EZ-Latch is the first truly universal external latch lock system. Most locks on the market are designed only for specific applications and require additional machining before they are ready for use making it difficult to select the right latch lock to correctly sequence the plates. The DME EZ-LATCH Lock, with its modular capabilities, addresses this limitation and, through its patented mechanical design provides safer and longer lasting performance.

Your benefits from using EZ-Latch locks

Providing A Controlled Sequencing Solution For Mass Production Moulds

The DME EZ-Latch Lock is the easy solution for all plate control application including 3 plate moulds, 2-stage ejection, early plate return, both stationary “cavity” and moving “core” side ejection (in place of high cost hydraulic cylinders).

Unlike any other lock on the market, the DME EZ-Latch Lock incorporates a positive mechanical lock avoiding the use of springs and/or friction devices a common source of product failure and even the occasional crashing of the tool. This safer solution provides a more consistent lock every cycle making it the preferred solution for mass production.

Designed For Ease of Installation Its standard design makes it easy to install straight out of the box.

DME EZ-Latch External Latch Locks

Positive and Precise Positioning of Floating Plates

Featuring

- Ideal for moulds with floating plates, including stripper plates & 3-plate moulds

- Floating plates are positively locked mechanically in place during mould opening and closing, preventing potential mould damage

- Reliable long-life performance through its unique design and use of nitride diffused material, avoiding coatings that can wear off during use

- Allows faster cycle times due to mechanical action vs latch locks that rely on springs or friction to lock plates

- Simplifies mould design while improving design flexibility

- Designed and engineered to hold large loads while saving space inside the mould

- Optional long latch bar for greater stroke

Benefits

There’s a reason DME has added its new external latch locks to its EZ line of products:

- EZ – to install

- EZ – to sequence (time) plates

- EZ – to use on thin plates

- EZ – used for all plate control needs

- EZ – to disassemble & maintain

Does not use springs, stripper/shoulder bolts or friction components

EZ-Latch offers several variants of product and implementation

We have developed simple, web based tool to help you select the EZ-LATCH you need for your mould.

For bottom last 2 stage injector

3-plate mould control

Bottom last sequence

Top last sequence

For ejector (both fix side and moving side)

Stay up to date

Are you interested in news and advices from our service areas?

Sign up for our newsletter and do not miss any seasonal advice nor any useful information